- Presenters:

- Hamed Layssi

- Duration:

- 45 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

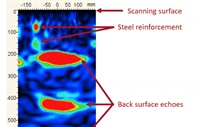

- The application of nondestructive testing and evaluation for detecting existing defects and anomalies in concrete structures will be presented. Proper inspection and assessment is an integral part of a successful repair and rehabilitation. A well-defined inspection will help asset owners and their consultants in identifying the location and extent of existing defects, and enabling them in selecting proper repair materials and optimizing the area that needs rehabilitation. Moreover, NDT methods can help identify potential defects that are not visible to the naked eye, such as early-stage delamination, corrosion, and other durability related issues. In this presentation, several cases in Canada will be demonstrated, where the results of nondestructive testing and evaluation have been used to help consultants and contractors with cost-effective and reliable repair planning. Applications of ground penetrating radar, ultrasonic pulse echo tomography, seismic tomography, will be discussed.

- Price:

- $0.00 - Base Price

- Bundle(s):

- Fall Conference Bundle

- Presenters:

- Dr. Jacob L. Borgerson

- Duration:

- 24 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Concrete placement and finishing defects raised by a member of the project team may indicate a greater (unobserved) structural concern, a long-term durability issue, or simply an aesthetic problem. Concrete defects can delay the project schedule, require costly investigation fees, and necessitate removal and replacement. This presentation is intended to tackle concrete placement and finishing defects faced by the concrete construction industry. Topics will include: cold joints, delaminations, dusting, honeycombing, form leakage, plastic shrinkage cracking, floor flatness/levelness, in addition to others. This presentation will discuss the causes of these concrete defects, techniques for evaluating various defects, and approaches for mitigating these problems. Attendees will be introduced to various evaluation methods (e.g., impact-echo, ultrasonic pulse velocity, ground penetrating radar, concrete coring, petrographic examination, etc.) and when their use is appropriate.

- Price:

- $0.00 - Base Price

- Presenters:

- Fred Goodwin

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This webinar will cover the basics of concrete, its composition, properties, and deterioration mechanisms.

- Price:

- $0.00 - Base Price

- Presenters:

- Peter Tarara | Chris White

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This presentation will cover technical considerations, repair techniques, concrete repair basics and the selection and use of repair materials.

- Price:

- $0.00 - Base Price

- Presenters:

- Mr. Jorge Costa, P.E.

- Duration:

- 100 minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- In this presentation, we will address the effect that corrosion has on our concrete infrastructure, including buildings, bridges, sea walls, cooling towers, docks, and many other reinforced concrete structures.

- Price:

- $0.00 - Base Price

- Presenters:

- Erik Villari | Michael Salera

- Duration:

- 45 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Using Unmanned Aerial Vehicles and Systems (aka UAVs aka Drones) continues to be a hot topic for engineers and designers. Within the past 10 years, we have seen technology change how we live, work, play and learn. These advances in technology have enabled humans to be more efficient as well as socially and environmentally conscious and connected. Advances in engineering technology and efficiency have expanded structural engineer’s roles in inspection services. This presentation will highlight drone utilization for exterior surveys and inspection, impact on the built environment, and how drones will continue to influence in the future. This includes areas that are too dangerous for humans or structures where rigging can be difficult or impossible as well as the cost benefits of using a drone. The presentation will also delve into the effectiveness and appropriate applications of drone usage, specifically for hands-on applications.

- Price:

- $0.00 - Base Price

- Presenters:

- Nigel Parker

- Duration:

- 29 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- The Avalon Mall parking facility is a four level above grade structure, consisting of three suspended parking levels (approximately 7,750sq.m. each) and one on-grade parking level connected to the existing mall with a new pedestrian bridge. RJC was the structural engineer of record. During construction of the parking structure extensive cracking of the suspended parking garage slabs was noted at two of the 24 pours. RJC undertook a visual assessment of the parking slabs in question to determine the extent of the noted cracking and determined over 750lin.m. of cracks ranging in size from 0.5mm to 6.5mm in width. Following the visual assessment destructive testing of the concrete was undertaken to determine its in-situ properties as well as to understand the full extent of the cracking.

- Price:

- $0.00 - Base Price

- Bundle(s):

- Fall Conference Bundle

- Presenters:

- Anirudh Goel | Charles Hammond

- Duration:

- 28 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- The presentation, through case studies, talks about emergency response services for structural issues encountered during construction of new design projects. Among other examples is an eleven story precast parking structure. The contractor observed significant diagonal faulted cracking of L-beams (supporting double-tee sections) near bearing locations, few days after pouring topping slab. In addition, inverted-tee girders were observed to be supported on cracked corbels at other locations. A quick turn around was required to mitigate any immediate life safety hazard posed by the structural distresses and buy time for thorough investigation, non-destructive testing, analyses, and repair design. Another example is a seven story precast parking structure. The structure was under construction and reportedly erected out of plumb. Poor concrete placing practices and poor weld detailing led to widespread cracking in multiple structural elements throughout the structure...

- Price:

- $0.00 - Base Price

- Presenters:

- David G. Tepke, PE, FACI

- Duration:

- 1 Hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This presentation will discuss new and recently updated industry standard codes and specifications, guides, certifications and educational training resources developed in the United States over the last decade for helping concrete restoration professionals effectively evaluate structures, and design, inspect and install quality concrete repairs. Types of resources will be distinguished to help engineers, contractors, inspectors, code officials and others determine how to select a resource for a particular need, and brief project examples will be used to highlight how some of the resources discussed might be used.

- Price:

- $0.00 - Base Price

- Presenters:

- Mr. Larry D. Olson

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Concrete repair projects are increasingly benefiting from the use of nondestructive evaluation (NDE) methods to diagnose and identify where internal concrete conditions need repair. By overlaying the results from multiple NDE methods, a data fusion approach combines, providing a more accurate surface and full-depth image of concrete bridge conditions for repair designs.

- Price:

- $0.00 - $0.00

- Presenters:

- Fred Goodwin

- Duration:

- 1 hour, 4 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Concrete is the most widely used construction material and can be durable for hundreds of years; however, the main cause of concrete deterioration is from corrosion of reinforcing steel. Steel is thermodynamically unstable and will eventually oxidize to a lower energy state. The rate of deterioration in new and existing structures can be modeled to predict the service life based on the severity of the service environment, the concrete quality, the ingress of deleterious materials, and other factors to various degrees of success. This presentation will provide an overview of many of the service life models currently in use and provide an evaluation protocol for their application related to both new and existing structures.

- Price:

- $0.00 - Base Price

- Presenters:

- Dave Fuller | Keith Kesner, P.E., S.E. | David G. Tepke, PE, FACI | John Landry | John McDougall, FICRI, CSRT | Aamer Syed

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This 60-minute session will be comprised of a 10-15 minute introduction to ACI 562, followed by a 45-minute discussion by a moderated panel of various experienced stakeholders in the concrete repair industry, including Specifiers, Contractors, Manufacturer/Distributors, and Owners.

- Price:

- $0.00 - Base Price

- Presenters:

- Andrew Jones

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This webinar covers when and why to use Clear Water Repellents on masonry and concrete.

- Price:

- $0.00 - Base Price

- Presenters:

- Dave Fuller

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This discussion focuses on addressing critical areas to help avoid costly issues when installing protective coatings and sealers.

- Price:

- $0.00 - Base Price

- Presenters:

- Mr. Richard First

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

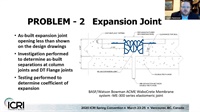

- This webinar will review the causes for cracking in concrete and the standard, preventative methods for addressing movement.

- Price:

- $0.00 - Base Price

- Presenters:

- Belin Wills | Ethan Namink

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This unique webinar specifically focuses on the technology, process & application of using high-pressure water to remove concrete, called Hydro Demolition.

- Price:

- $0.00 - Base Price

- Presenters:

- Mr. Eric Muench | Dan Wald

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Industry experts Eric Muench and Dan Wald will discuss how to best select the right traffic bearing waterproof membrane technology for concrete protection.

- Price:

- $0.00 - Base Price

- Presenters:

- John S. Lund

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- The new ACI 563-25 repair specifications include information on Crack Repair, Galvanic Anodes, Protective Membranes, Overlays, Precast Concrete Repair, Post-Tensioned Concrete Repair and Architectural Concrete Repair.

- Price:

- $0.00 - $0.00