- Presenters:

- Dave Fuller

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Short Description:

- This discussion focuses on addressing critical areas to help avoid costly issues when installing protective coatings and sealers.

- Price:

- $0.00 - $40.00

- Presenters:

- Pete Haveron

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Short Description:

- This webinar will discuss the keys to proper surface preparation including establishing the appropriate level of surface profile, evaluating the concrete substrate and the material being installed to determine the correct level of preparation as well as the correct methods and tools to achieve that level.

- Price:

- $0.00 - $40.00

- Presenters:

- Richard First

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Short Description:

- This webinar will review the causes for cracking in concrete and the standard, preventative methods for addressing movement.

- Price:

- $0.00 - $40.00

- Presenters:

- Belin Wills | Ethan Namink

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Short Description:

- This unique webinar specifically focuses on the technology, process & application of using high-pressure water to remove concrete, called Hydro Demolition.

- Price:

- $0.00 - $40.00

- Presenters:

- Eric Muench | Dan Wald

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Short Description:

- Industry experts Eric Muench and Dan Wald will discuss how to best select the right traffic bearing waterproof membrane technology for concrete protection.

- Price:

- $0.00 - $40.00

- Presenters:

- Michael Sprinkel

- Duration:

- 37 Minutes

- Format:

- Audio and Video

- License:

- Short Description:

- The prestressed beams in the Hampton Roads Bridge Tunnel Approach Spans were fabricated in about 1960 (west bound lane) and 1970 (east bound lane). The spans are 50-ft and 75-ft, respectively. The brackish water environment caused corrosion and failure of the bottom strands and deterioration and spalling of the cover concrete in many beams. A project in 2018 strengthened 30 of the more deteriorated beams as an alternative to posting or replacing the bridges. Carbon fiber composite wrap (CFCW) and external post-tensioning (PT) were used to strengthen the beams. Prior to construction, a PT mockup was done with one 50-ft (flexible filler) and one 75-ft (grout) beam to demonstrate that the contractor had the materials, equipment and staff to successfully do the external PT. This presentation describes the project’s mockups and construction and the anticipated increase in strength to be obtained from application of the CFCW and external PT.

- Price:

- $15.00 - $25.00

- Bundle:

- Fall Conference Bundle

- Presenters:

- Edmund L Baum

- Duration:

- 17 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Construction errors such as the misplacement of reinforcing steel and modifications like the addition of openings traditionally required intrusive repair methods. The addition of structural steel support or enlargement of the concrete elements is often not aesthetically pleasing or practical and the cost and time impacts are onerous. FRP strengthening solutions are non-intrusive, practical, and can be implemented quickly without major impact on the other building trades. The presentation will guide the audience through the feasibility assessment of FRP strengthening and implementation of the strengthening solution. The roles of the various parties, including the Engineer of Record, the FRP Design Engineer, the General Contractor, the Structural Contractor, and the FRP Installer, will be illustrated. Photographs of completed repairs will be presented.

- Price:

- $15.00 - $25.00

- Bundle:

- Fall Conference Bundle

- Presenters:

- Brent Anderson, P.E.

- Duration:

- 40 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

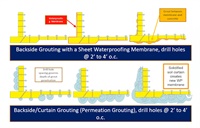

- Dealing with water is always a challenge when constructing a new structure. Whether it is water infiltration that was expected, or water manages to circumvent pre-planned waterproofing methods, it can wreak havoc on the building and interfere with construction schedules. The term “belt and suspenders” is often used in waterproofing and there is a good reason for it. Water chooses the path of least resistance, and many times that path is not discovered until it is too late. There are many methods of water control that can be implemented before, during and after a structure is completed. This presentation will focus on water control methods for new construction that can be implemented during or after the construction process.

- Price:

- $15.00 - $25.00

- Presenters:

- David G. Tepke

- Duration:

- 42 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Repairing and extending the service life of concrete in severe environments first requires that one understands what may be considered severe why it may be considered so. This presentation will discuss the ways in which different organizations and technical committees around the world define ‘severe environments’ for concrete structures; types of deterioration mechanisms and materials-related distress that may severely and quickly deteriorate concrete, type of structures with potentially severe environments, and U.S. geographical considerations.

- Price:

- $15.00 - $25.00

- Bundle:

- Fall Conference Bundle

- Presenters:

- Peter Barlow

- Duration:

- 36 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- A significant percentage of repairs are performed during the course of constructing new structures. Once a construction anomaly or error occurs the first concerns are for life safety and schedule impact. A review of the steps necessary to successfully perform repairs and minimize impacts to the ongoing construction. Examples of challenging problems and the traditional and non-traditional solutions to these problems will be discussed.

- Price:

- $15.00 - $25.00

Please wait ...