- Presenters:

- Rick Edelson, P.E.

- Duration:

- 30 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- The ACI 562-16 Repair Code is primarily intended for the Licensed Design Professional for providing the requirements necessary for assessing and designing repairs and rehabilitation of existing concrete structures.

- Price:

- $0.00 - $15.00

- Presenters:

- Keith Kesner, P.E., S.E.

- Duration:

- 39 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- In June 2016, ACI published ACI 562-16,” Code Requirements for Assessment, Repair and Rehabilitation of Existing Concrete Structures and Commentary”. ACI 562-16 replaces ACI 562-13 as a standard for the repair of existing concrete structures. Significant changes to ACI 562-16 include improvements in terminology for consistency with ISO, ASCE and other documents, inclusion of requirements for level of repair based upon extent of damage present, and revisions to the interface bond provisions. The video will describe the concrete repair code, focusing on key changes made to the code and describe how the code is to be used on concrete repair projects.

- Price:

- $0.00 - $15.00

- Presenters:

- Sivakumar Munuswamy

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Many practicing engineers, developers, property owners and property managers, concrete restoration contractors and professionals generally perceive that the existing unbonded single strand post-tensioned (PT) structural elements cannot be altered, add or remove portions or whole of the floor systems for rehabilitation or for dynamic and adaptive repurposing by converting the existing structure from original design purpose, into a change in use. For example, an office building converted into a residential building or a hotel hospitality building. Of late, these types of conversions are increasing in trend especially in the urban environment, driven by migration from the impact of the COVID 2019 pandemic and an increasing awareness of climate change, and a need for sustainable and efficient use of existing structures. Through a case-study of an ongoing adaptive repurposing structure project, this presentation burst the myth on adaptability of unbonded PT structural systems.

- Price:

- $0.00 - Base Price

- Presenters:

- David Flax

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This presentation will cover a number of ways to accomplish better-looking repairs. But what about those projects where ugly repairs have already been made? This presentation will also address how to improve the appearance of existing, unsightly repairs.

- Price:

- $0.00 - $0.00

- Presenters:

- Hamed Layssi

- Duration:

- 45 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

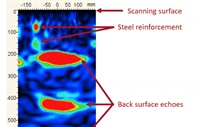

- The application of nondestructive testing and evaluation for detecting existing defects and anomalies in concrete structures will be presented. Proper inspection and assessment is an integral part of a successful repair and rehabilitation. A well-defined inspection will help asset owners and their consultants in identifying the location and extent of existing defects, and enabling them in selecting proper repair materials and optimizing the area that needs rehabilitation. Moreover, NDT methods can help identify potential defects that are not visible to the naked eye, such as early-stage delamination, corrosion, and other durability related issues. In this presentation, several cases in Canada will be demonstrated, where the results of nondestructive testing and evaluation have been used to help consultants and contractors with cost-effective and reliable repair planning. Applications of ground penetrating radar, ultrasonic pulse echo tomography, seismic tomography, will be discussed.

- Price:

- $0.00 - Base Price

- Presenters:

- Mr. Kristian Krc | Mr. David T Ford

- Duration:

- 44 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Arrowhead Stadium originally opened in 1972 and is known to be the home to the Super Bowl Champions Kansas City Chiefs. Renovations of the stadium completed in 2010 included adding luxury suites on the club level of the stadium. This meant that the upper seating bowl not only had to seat more than 34,000 Chief fans but also act as a "roof" for the new luxury suites. The upper seating bowl comprises L-shaped precast concrete seating risers spanning from cast-in-place concrete raker beams and is divided by sixteen expansion joints. In 2018, the planning for the upper seating bowl waterproofing program began. The goal for the repair project was to implement waterproofing upgrades to protect the concrete for the next 10 years. To add to the challenge of a large-scale waterproofing and structural repair project, the construction efforts had to include coordination with simultaneous seat replacement to be completed in a single off-season.

- Price:

- $0.00 - Base Price

- Presenters:

- Baruch Gedalia

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This presentation aims at providing clear and down to earth definitions of what Post-Tensioning systems are, the different repair strategies related to these systems, and critical factors to be accounted for during the design and execution of any intervention on a Post-Tensioning slab.

- Price:

- $0.00 - $0.00

- Presenters:

- Mr. Shayan Yazdani

- Duration:

- 40 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Arlington Memorial Bridge is a reinforced concrete spandrel arch bridge that connects Washington, DC and Virginia across the Potomac River. After over 85 years in service, the bridge started exhibiting signs of deterioration, including reinforcement corrosion. As part of a major rehabilitation effort to extend the bridge’s service life, targeted cathodic protection (CP) systems were installed in the arch cross-walls, floors, and under arches to mitigate and prevent corrosion. The implemented CP system consisted of galvanic and two-stage anodes to mitigate corrosion. Galvanic anodes were installed in the repair areas to prevent the ring anode affect and ensure a durable concrete repair. The two-stage anodes were installed in areas of concrete which were actively corroding without signs of concrete deterioration.

- Price:

- $0.00 - Base Price

- Bundle(s):

- Fall Conference Bundle

- Presenters:

- Dr. Jacob L. Borgerson

- Duration:

- 24 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Concrete placement and finishing defects raised by a member of the project team may indicate a greater (unobserved) structural concern, a long-term durability issue, or simply an aesthetic problem. Concrete defects can delay the project schedule, require costly investigation fees, and necessitate removal and replacement. This presentation is intended to tackle concrete placement and finishing defects faced by the concrete construction industry. Topics will include: cold joints, delaminations, dusting, honeycombing, form leakage, plastic shrinkage cracking, floor flatness/levelness, in addition to others. This presentation will discuss the causes of these concrete defects, techniques for evaluating various defects, and approaches for mitigating these problems. Attendees will be introduced to various evaluation methods (e.g., impact-echo, ultrasonic pulse velocity, ground penetrating radar, concrete coring, petrographic examination, etc.) and when their use is appropriate.

- Price:

- $0.00 - Base Price

- Presenters:

- Fred Goodwin

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This webinar will cover the basics of concrete, its composition, properties, and deterioration mechanisms.

- Price:

- $0.00 - Base Price

- Presenters:

- Peter Tarara | Chris White

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This presentation will cover technical considerations, repair techniques, concrete repair basics and the selection and use of repair materials.

- Price:

- $0.00 - Base Price

- Presenters:

- Mr. Jorge Costa, P.E.

- Duration:

- 100 minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- In this presentation, we will address the effect that corrosion has on our concrete infrastructure, including buildings, bridges, sea walls, cooling towers, docks, and many other reinforced concrete structures.

- Price:

- $0.00 - Base Price

- Presenters:

- David Bewley | Christian Stone, M.S., M.Phys.

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This session describes how novel corrosion management techniques have been used to extend the life of a variety of heritage structures, including a church, a bridge and even a castle.

- Price:

- $0.00 - Base Price

- Presenters:

- Stephen Lucy

- Duration:

- 49 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Dallas City Hall and Plaza are recognized by many due to the opening scenes of Dallas, the television show. What is less known is that the structure is a significant early example of bonded post-tensioned concrete which was utilized throughout the superstructure and two-story parking garage constructed beneath the plaza. Opened in 1977, the parking garage is a two-way bonded post-tensioned concrete slab with unreinforced drop panels supported by flared circular concrete columns. The garage covers two city blocks, extends under two adjacent multi-lane streets, and supports mature landscaping, pool, fountain, and up to 11’-0” of soil. In 2017, several square feet of a drop panel fell from the structure and subsequent observations found multiple locations of drop panel and column capital failures. A structural investigation including destructive and non-destructive testing, and analysis of the existing structure was undertaken to determine the cause of the failures.

- Price:

- $0.00 - Base Price

- Presenters:

- Erik Villari | Michael Salera

- Duration:

- 45 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Using Unmanned Aerial Vehicles and Systems (aka UAVs aka Drones) continues to be a hot topic for engineers and designers. Within the past 10 years, we have seen technology change how we live, work, play and learn. These advances in technology have enabled humans to be more efficient as well as socially and environmentally conscious and connected. Advances in engineering technology and efficiency have expanded structural engineer’s roles in inspection services. This presentation will highlight drone utilization for exterior surveys and inspection, impact on the built environment, and how drones will continue to influence in the future. This includes areas that are too dangerous for humans or structures where rigging can be difficult or impossible as well as the cost benefits of using a drone. The presentation will also delve into the effectiveness and appropriate applications of drone usage, specifically for hands-on applications.

- Price:

- $0.00 - Base Price

- Presenters:

- Nigel Parker

- Duration:

- 29 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- The Avalon Mall parking facility is a four level above grade structure, consisting of three suspended parking levels (approximately 7,750sq.m. each) and one on-grade parking level connected to the existing mall with a new pedestrian bridge. RJC was the structural engineer of record. During construction of the parking structure extensive cracking of the suspended parking garage slabs was noted at two of the 24 pours. RJC undertook a visual assessment of the parking slabs in question to determine the extent of the noted cracking and determined over 750lin.m. of cracks ranging in size from 0.5mm to 6.5mm in width. Following the visual assessment destructive testing of the concrete was undertaken to determine its in-situ properties as well as to understand the full extent of the cracking.

- Price:

- $0.00 - Base Price

- Bundle(s):

- Fall Conference Bundle

- Presenters:

- Mr. Daniel Mazzei | Adam Logan

- Duration:

- 38 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- A follow-on presentation to the discussion of our evaluation of over 1500 tire and lube facilities across the United States that prescribed immediate repairs where necessary, reinforcement where deterioration reduced capacity below acceptable levels and coatings necessary to protect structural steel and structural concrete (i.e. our 2019 Philadelphia presentation). This will be an in-depth presentation of how repairs were specified for (3) specific types of structures. The (3) structure types are exposed structural concrete, composite metal deck and fully reinforced form deck slabs all supported by steel structures and reinforced concrete walls. Presentation will include before, during and completion photos of each project discussed. Again, touch on the evaluation processes to include demand to capacity ratios review, evaluation system and inspection form, triggers to determine when shoring is necessary, calculation of capacities per AISC 360, ACI 318, ACI 562 and local building codes.

- Price:

- $0.00 - Base Price

- Presenters:

- Alfred Gardiner

- Duration:

- 34 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Two projects will be explored in this presentation. The first is a concrete structure which for 20 years was exposed to extreme heat. The second is a structure which was exposed to extreme vibrations. Both these structures were integral parts of manufacturing processes and required limited down time to repair. The questions needing to be answered were: what is the condition of the existing concrete and what are the repair options for these structures. We turned to non-destructive techniques to evaluate these structures. Non-destructive techniques can provide insight into structures when accompanied by experienced engineers and petrographic analysis. Repair options were provided at the end of our evaluation leading to reduced down time and well-planned repairs.

- Price:

- $0.00 - Base Price

- Bundle(s):

- Fall Conference Bundle

- Presenters:

- Anirudh Goel | Charles Hammond

- Duration:

- 28 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- The presentation, through case studies, talks about emergency response services for structural issues encountered during construction of new design projects. Among other examples is an eleven story precast parking structure. The contractor observed significant diagonal faulted cracking of L-beams (supporting double-tee sections) near bearing locations, few days after pouring topping slab. In addition, inverted-tee girders were observed to be supported on cracked corbels at other locations. A quick turn around was required to mitigate any immediate life safety hazard posed by the structural distresses and buy time for thorough investigation, non-destructive testing, analyses, and repair design. Another example is a seven story precast parking structure. The structure was under construction and reportedly erected out of plumb. Poor concrete placing practices and poor weld detailing led to widespread cracking in multiple structural elements throughout the structure...

- Price:

- $0.00 - Base Price

- Presenters:

- Chris Dumford

- Duration:

- 1 hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Terracon performed an investigation of a five-story concrete constructed building which had sustained significant damage, both before and after Hurricane Matthew in Nassau, Bahamas.

- Price:

- $0.00 - Base Price

- Presenters:

- Kip Gatto, P.E.

- Duration:

- 29 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This video will illustrate an example of how various sections of ACI 562 are applied in the execution of a complex repair project, the repurposing of a historic train deck into a transportation hub for light rail trains and busses. Methods of evaluation and analysis, as guided by ACI 562, will be presented with a discussion of how these provisions lead to various repair approaches presented to the owner.

- Price:

- $0.00 - Base Price

- Presenters:

- Pat Martin, P.E.

- Duration:

- 26 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This video will discuss how the requirements of ACI 562-16 are used in the evaluation and repair of parking structures. It will take participants through a representative garage project, utilizing Design Example 1 from the Guide to the Use of ACI 562 as the basis. Evaluation and design considerations will be discussed relative to the Repair Code as well as QA/QC and the Engineers' Role during construction.

- Price:

- $0.00 - Base Price

- Presenters:

- Chuck Larosche, P.E.

- Duration:

- 23 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This video will illustrate an example of how various sections of ACI 562 are applied in the execution of a Precast/Prestressed Double-Tee repair project. Methods of evaluation and analysis, as guided by ACI 562, will be presented with a discussion of how these provisions can lead to various repair approaches.

- Price:

- $0.00 - Base Price

- Presenters:

- Keith Kesner, P.E., S.E.

- Duration:

- 1 Hour

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- Codes and standards are developed for use by design professionals; however, the use of codes and standards significantly impacts Owners and Contractors. The ACI 562 code was motivated by the poor performance of repaired concrete structures, specifically premature failure of repairs and limited durability of repaired structures. Development of the code was intended to benefit owners and contractors by improving performance and perceptions regarding repairs to existing structures.

- Price:

- $0.00 - Base Price

- Presenters:

- Kelly Streeter | Daniel Gordeyeva

- Duration:

- 42 Minutes

- Format:

- Audio and Video

- License:

- Access for 6 month(s) after purchase.

- Short Description:

- This presentation will look at how technology is used to perform condition assessments at height and in places with difficult access utilizing a virtual toolbox that includes a wide range of instruments and tools for non-destructive evaluation and testing, and a fleet of drones, each of which has a different use. The presentation will discuss how to use drones and tools at height; how the industry is using drones in new ways; and how some municipalities are changing policies to adapt, especially with regard to facade inspections.

- Price:

- $0.00 - Base Price